Single Storey Home Extensions

Open Plan Living

A growing family calls for more room. But did you know that relocating isn’t always the best option? These days, you can easily increase the size of your house with a single storey extension that will transform your space and provide for the freedom to really spread out. In many cases, the cost of a home extension can work out significantly cheaper than a new home build. You’ll be able to stay in the area you love and you won’t need to go through the stress of moving. Whether you want to remodel or add an extra room out the back, Cameron Construction has all your needs sorted.

Quality home extensions

We can bring your dream ideas to life. This is because Cameron Construction has nearly 50 years of collective experience working across all kinds of projects. Our home extensions are constructed using quality materials and we always provide an exceptional level of craftsmanship. Rest assured that we can match the original design of your home to ensure that your new addition looks and feels perfect in every way.

Renovation costs for single storey homes

Everyone has a different vision for their home and a different budget to work with. We believe that cost shouldn’t be a hindrance to your new home extension or renovation. That’s why the team at Cameron Construction takes the time to understand what you want to achieve. This allows us to create the best designs that match your changing needs and lifestyle. We specialise in the upper storey and ground-floor renovations in Melbourne incorporating functional zoning, low energy guidelines and excellent customer service to enable the design and construction of your new house extension with minimum fuss and cost.

A Cameron Home Improvement will increase the value of your property and is the best form of investment for your future.

Our master builders expertly assess your current property and advise as to how they can make your home improvement dreams a reality at the best cost.

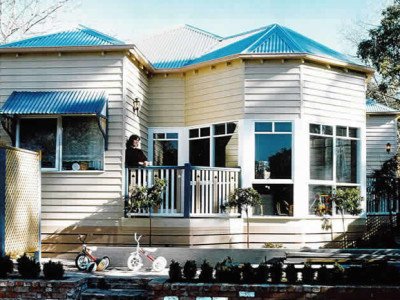

Click on the image below to view examples of the Gallery.

Book a consultation today

Get in touch with our home renovation builders to find out more about what we have to offer. We can help with single-storey extensions, double-storey extensions and more.

FAQs

How much will it cost to add an additional storey to my home?

Most people assume that the cost of building single storey home extensions is cheaper than building a double-storey extension. But that isn’t always necessarily true. While going out rather than up means that you can keep your original roof, going up takes advantage of the existing footing structure wish can save thousands. Going up also allows you to extend the streetscape presence of your house which in turn can increase the value of your home. The cost savings of extensions can also mean that further improvements such as kitchen renovation or a bathroom renovation are possible.

Cameron Construction’s pricing is highly competitive. We specialise in saving you thousands of dollars when building your extension or house renovation because of the proven process and long term experience in the industry.

Request a quote or Phone Free No Obligation Consultation to discuss your home extension needs.

Cameron Construction can provide an assessment and a comprehensive written quotation for your Home Extension with your particular budget in mind. We give you an All-Inclusive Fixed Cost Price Contract for added security.

Do you need planning permission for a single storey extension?

There’s welcome news for homeowners as the permitted development rules have recently been relaxed. You can now build an extension without planning permission of up to six metres (or eight metres if your house is detached). This means that any work meeting these requirements can be carried out without council approval.

How much will a single storey home extension cost?

The cost of a single storey house extension will depend on what work is actually being carried out. For instance, less complicated projects such as basic remodelling can be done for considerably less than adding another room out the back. It’s always best to speak with an expert team to get an idea of what they charge before work commences.